Inward-opening

folding doors

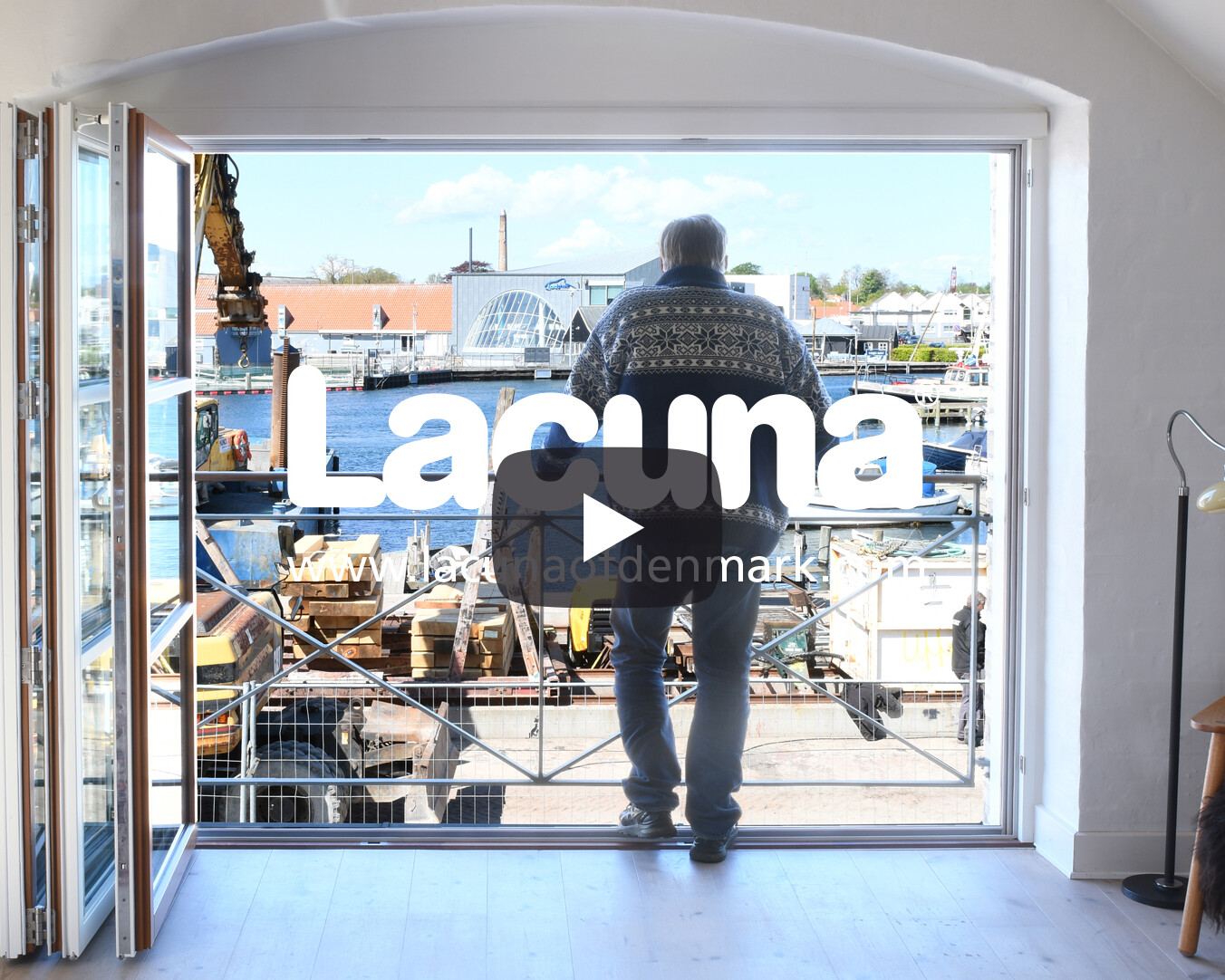

An inward-opening folding door is ideal if you have e.g. a small balcony. With an inward-opening folding door you get a large opening on to your balcony without the door taking up space on the balcony as it opens into the room. In this way you get the most out of your outdoor area. We always manufacture the folding door to meet your needs and wishes. We can change e.g. the width, height, handle and glass types, as well as the top frame.

CHOICE OF

MATERIALS

It is possible to choose from a number of wood species for your inward-opening folding door: oak, beech and mahogany. At Lacuna, we use environmentally friendly processes in our treatment of the wood, which make it as maintenance free as wood / alu. Please read about our TMT Composite® treatment below.

TMT

COMPOSITE®

TMT Composite® (Thermally Modified Timber) is the concept of Lacuna’s advanced heat-treatment, which we use on beech for the folding doors. No chemicals whatsoever, only heat, is used in the treatment. Through the TMT® process the timber obtains durability class 1, as teak, and a humidity of about 5.5%, making the modified timber very suitable for folding doors, as dimensional stability is extremely important for an airtight product that should not need adjustment during changing weather conditions (moisture / draught).

The TMT Composite® also provides much better insulation, as the wood cannot absorb moisture like untreated wood. The result is a folding door that lasts for many, many years.

MAHOGANY

AND OAK

We can also supply European oak and FSC certified sapele mahogany, without TMT Composite® treatment, oiled in a number of color tints.

SURFACE TREATMENT

OPTIONS

It is possible to chose among a number of surface treatments – either painted or oiled. More than 90% of what we manufacture is painted TMT beech. We can paint in all colors, and also in transparent paint with UV filter on e.g. TMT Composite®.

We at Lacuna paint our inward-opening folding doors like in the automotive industry, priming our products twice with sanding inbetween and applying two or three layers of top coat, depending on colour. The result is a super smooth surface (many believe it is painted aluminium) that is much more durable than through the traditional technique used in the window industry.

PAINTED

SURFACES

In line with our principles, we only use environmentally friendly, water-based and proven durable paints.

You can choose from a large number of RAL and NCS colors.

For items that are not particularly exposed, no paint treatment is required the first 25-35 years.

OILED

SURFACES

For our oil-treated mahogany or oak products, we use cold-pressed linseed oil that seals the wood surface much better than water or turpentine-based oils.

Please note that oil-treated products should be re-treated at least three times in the first year after installation. This will saturate the wood and prevent drying cracks. Subsequently, depending on how much the parts are exposed to the weather, they should be re-treated twice a year. We can now also offer a transparent UV surface treatment for our Sapelli mahogany and oak products. The UV surface treatment is similar to painting and the elements do not need to be treated for the first many years.

COLOUR

COMBINATIONS

Modern buildings often have dark frames externally. Here often a lighter, possibly white colour is chosen internally. We can paint our folding doors in two or three colour combinations – also if desired, for example, oiled mahogany combined with a white colour.

We can also paint several types of texture as well as a colourless paint – like varnish.

Some options are:

1. Combination of RAL 9005/9010

2. Combination of RAL 7016/9010

3. Mahogany, combined with 9010 and linseed oil

4. Mahogany, oiled with cold-pressed linseed oil

5. Mahogany, with cold-pressed black pigmented linseed oil

6. Oak, oiled with cold-pressed black pigmented linseed oil

7. Oak, oiled with cold-pressed linseed oil

DIMENSIONS

AND OPENINGS

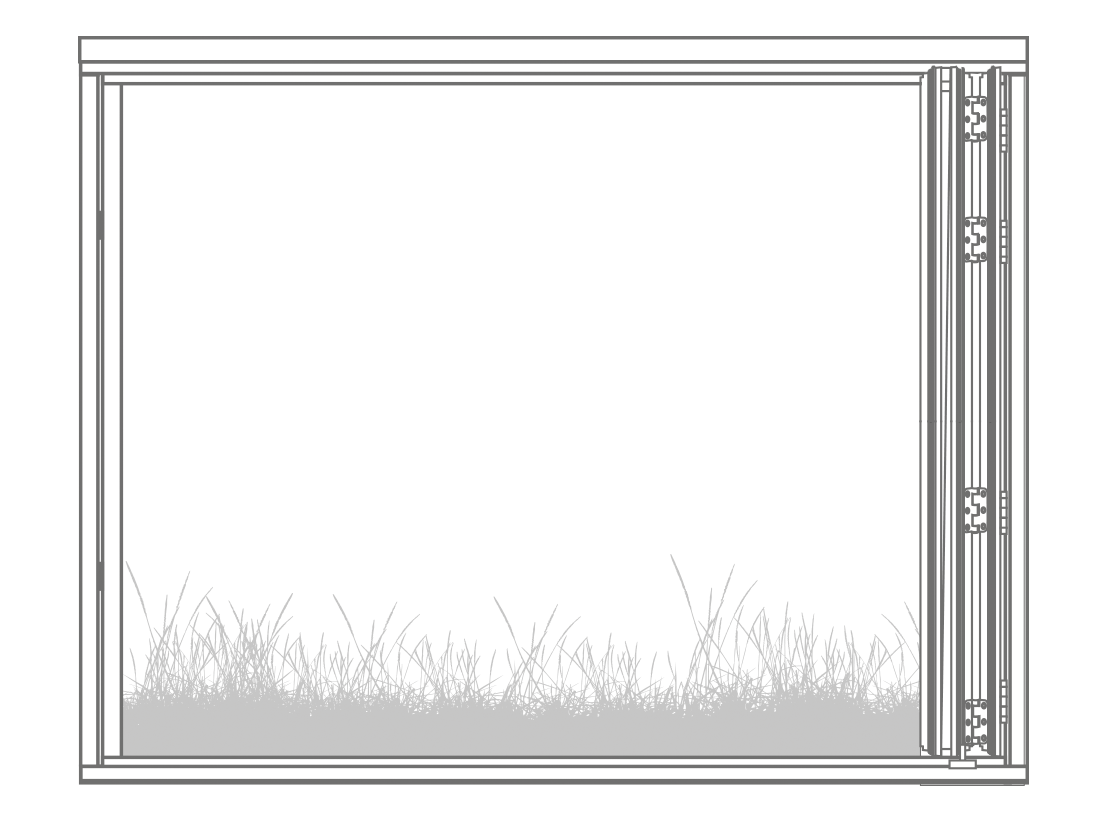

The Lacuna inward-opening folding doors are manufactured to individual measures from 1.5 m to 6 m width and max. 2.8 m height. The individual door leaves can be up to 100 cm wide with two layers of glass and 90 cm with three layers of glass.

The Lacuna folding door can be supplied in combinations with 3-9 leaves and with numerous options for the location of the master leaf.

At renovations and extensions, it is important to ensure that the building construction is designed for, or can be adapted to the selected option.

MILLIMETRE

PRECISION

All the working is done on CNC robots with a precision of a tenth of a millimetre.

Our quality control and CNC robots eliminate the risk of human error and too large tolerances.

Opening

The opening on a Lacuna folding door is G…..R…..E…..A….T…… It is customized and manufactured for each project. We are able to customize our doors so they fit with other types of windows and doors in your home. There are endless possibilities and combinations with regard to width, height, frame type, colour internally and externally, glass type, handle type and much more. All in all you always get a folding door that exactly matches the look you want.

OPENING ON

TRADITIONAL SLIDING DOORS

The traditional lift and slide doors have openings of about 45%.

LARGER OPENING

WITH A LACUNA FOLDING DOOR

On a Lacuna folding door the opening area is a whole 90%.

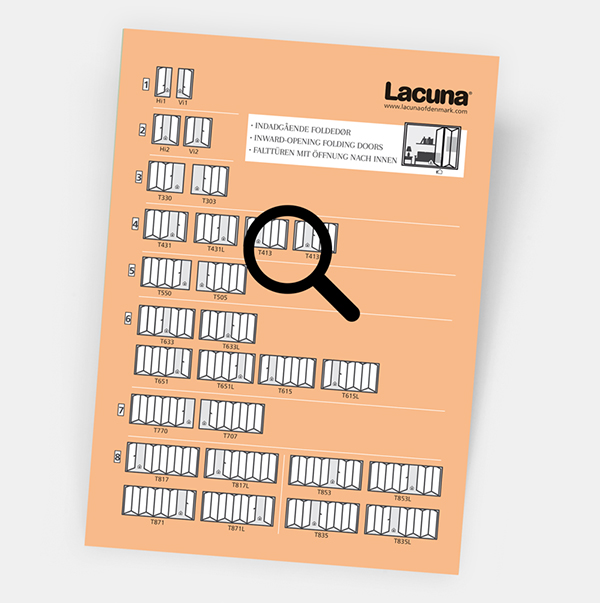

NUMBER OF LEAVES AND

LOCATION OF THE MASTER LEAF

There are numerous options and combinations when it comes to the number of leaves and the location of the master leaf. In order to be able to fold the door, an odd number of door leaves are required. This means that on a door with an odd number of leaves, all leaves fold to the same side. If the door has an even number of leaves, these will be divided so that an odd number of leaves open to each side.

A few opening options are shown here, with varying number of leaves.

GLASS

The glass is a major part of a folding door. It is therefore important that the choice of glass is correct. Besides two or three-layer glass, a Lacuna door can be supplied with glass that meets different requirements and functions. We only use quality glass from the leading glass manufacturers for the construction industry. We offer a wide selection and will readily advise you.

Please note that the more energy-efficient glass you choose the greater care you take of the environment. It is worthwhile investing in energy-efficient glass as the door and glass are built to last for many years.

CHOICE

OF GLASS

Most of our doors are supplied as facade folding doors where low-energy glass in either two or three layers is selected. However, our doors can be supplied with many other types of glass:

• Low energy

• Noise reduction

• Safety (Toughened and/or laminated glass)

• Solar control

• Self-cleaning

• Translucent glass types

• Glass with integrated blinds etc.

INTERNAL

GLASS BEADS

Unlike most other Scandinavian manufacturers of doors and windows, the glass in a Lacuna folding door is fitted from the inside. The glass beads are thus well protected inside, giving a number advantages: less maintenance, as there are no external joints, and greater security against burglary, as the glass beads cannot be removed by intruders.

DESIGN DETAILS

Lacuna offers flexibility in its design. This means that you can freely choose whether you want your folding doors without glazing bars, with helima integral bars, standard glazing bars, panels or perhaps with breaking transoms.

GLAZINGBARS

You have the option of choosing many different widths of the bars: 19 mm, 25 mm, 36 mm and 42 mm, with different types of profiles. In addition, you can get transoms (horizontal post) in 55 mm, 75 mm and 110 mm.

LARGE NON-BROKEN

SURFACES

The majority of our customers choose a door without glazing bars or fillings.

The wide door leaves, in a very thin frame, give a stylish and simple impression.

FOLDING DOOR

GLAZING BARS

Lacuna manufactures several different types of glazing bars and transoms. Most of the customers who want glazing bars in their inward-opening folding door choose 25 mm moulded bars with what we also call farmhouse profile on the inside. This design is also available in widths of 19mm, 36mm and 42mm. For all widths, an internal softline profile is also available, which gives a simple and modern impression that matches the style of new buildings. All of our glazing bars are externally tenoned in the frame (not glued to the glass) and cannot fall off.

HELIMA

GLAZING BARS

As an alternative to the traditional glazing bars, we also offer Helima bars. There are bars built in between the glass panes. Thus, there are no bars on the outside or inside of the door. Helima is price-attractive and has a great advantage when it comes to cleaning. The bars are available in several widths: 18mm, 26mm and 45mm.

TRANSOMS/

HORIZONTAL POSTS

if you want wider posts, we also make 55 mm, 75 mm and 110 mm horizontal transoms. These are continuous and thus divide the glass in the door. The transoms are, of course, completely integrated into the design of the frame.

PANELS

Lacuna also supplies panels that are flat or raised. The panels are not solid but laminated with a high-insulating material for the best possible insulation. Panels are supplied in the same colour as the door.

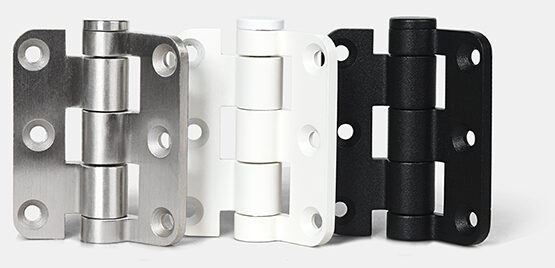

HINGES &

HANDLES

The Lacuna products can be exposed to powerful corrosive forces in e.g. Greenland and other coastal areas, with sometimes up to 7% salt content in the water.

At Lacuna we do not distinguish between where the elements are to be installed. All Lacuna products are manufactured in the same high quality.

CORROSION-RESISTANT

MATERIALS

We want the door including ironmongery to stay beautiful without corrotion for its entire life. We know that there are many different conditions that affect ironmongery. Particularly coastal areas can be a challenge for the stainless steel, so all parts are therefore treated with protective oil. Lacuna recommends regular maintenance and washing to keep the ironmongery and door clean. All hinges and handles are made of stainless steel and are available in black, white or steel.

Please read our maintenance guide.

1

2

VISIT OURSHOWROOM NOW

Get a short visual presentation.